Maintaining impeccably clean food preparation equipment is a non-negotiable cornerstone of any food service operation, from large-scale commercial kitchens to home cooking environments. Effective cleaning goes beyond mere aesthetics; it is a critical practice for ensuring food safety, preserving equipment functionality, complying with health regulations, and ultimately protecting consumer health and business reputation. This guide details the systematic approaches, best practices, and profound importance of this essential task.

Why Proper Cleaning is Non-Negotiable

The consequences of inadequate cleaning are severe and multifaceted. Primarily, it directly impacts public health. Residual food particles and moisture create an ideal breeding ground for pathogenic bacteria like Salmonella, E. coli, and Listeria, which can lead to foodborne illness outbreaks. Furthermore, built-up grease, carbon deposits, and mineral scale can drastically reduce equipment efficiency—ovens may heat unevenly, slicers can become dull and dangerous, and refrigeration coils may overwork, leading to higher energy costs and premature breakdowns. From a regulatory standpoint, health inspectors mandate strict cleanliness standards, and failures can result in fines, conditional passes, or even operational shutdowns.

The Core Principles: Clean vs. Sanitize

A fundamental concept is understanding the distinction between cleaning and sanitizing. Cleaning is the physical removal of visible food debris, grease, and dirt from surfaces using detergent, water, and mechanical action. Sanitizing is the subsequent step that reduces the number of microorganisms on a cleaned surface to safe levels, as defined by public health codes. A surface must be thoroughly cleaned before it can be effectively sanitized, as organic matter can shield bacteria from sanitizing agents.

The Standard Cleaning & Sanitizing Procedure

This four-step process is universally applicable to most food contact equipment:

- Pre-clean: Remove excess food waste by scraping, wiping, or rinsing.

- Wash: Clean with hot water (at least 110°F/43°C) and an appropriate detergent. Use brushes or pads to scrub surfaces.

- Rinse: Rinse thoroughly with clean, hot water to remove all detergent residue.

- Sanitize: Apply an approved sanitizer (e.g., chlorine bleach solution, quaternary ammonium, iodine) at the correct concentration and contact time.

- Air-Dry: Allow equipment to air-dry completely. Using a cloth can re-contaminate the surface.

Cleaning Different Types of Equipment

Protocols must be adapted based on the equipment's material, complexity, and function.

1. Fixed and Large Equipment (Ovens, Fryers, Grills)

These often require specialized procedures. For example, commercial fryers need daily filtering of oil and periodic boiling-out with detergent and water to remove polymerized grease. Flat-top grills require specific grill stones or scrapers for cleaning while at specific temperatures, followed by seasoning.

2. Mechanical Equipment (Slicers, Mixers, Food Processors)

Always disconnect power first. These items must be disassembled as per the manufacturer's manual. Blades and removable parts should be washed, sanitized, and air-dried separately. The motor housing should be wiped down with a damp, sanitized cloth—never immersed.

3. Stainless Steel Surfaces and Tables

Use cleaners designed for stainless steel to avoid pitting and damage. Always wipe in the direction of the grain. Avoid abrasive pads that can cause microscopic scratches where bacteria can hide.

4. Refrigeration Units

Schedule regular defrosting and cleaning. Remove all food, shelves, and drawers. Wash interior surfaces with a baking soda solution or mild detergent to neutralize odors, rinse, sanitize, and dry completely before restocking.

| Sanitizer Type | Common Concentration | Contact Time | Key Considerations |

|---|---|---|---|

| Chlorine (Bleach) | 50-100 ppm | ≥ 7 seconds | Effective, inexpensive. Degrades quickly, corrosive, sensitive to pH and organic matter. |

| Quaternary Ammonium (Quats) | 200 ppm | ≥ 30 seconds | Odorless, non-corrosive, stable. Less effective against some viruses. Can be inactivated by certain detergents. |

| Iodophors | 12.5-25 ppm | ≥ 30 seconds | Effective, acts as an indicator (color loss). Can stain plastics and porous surfaces. |

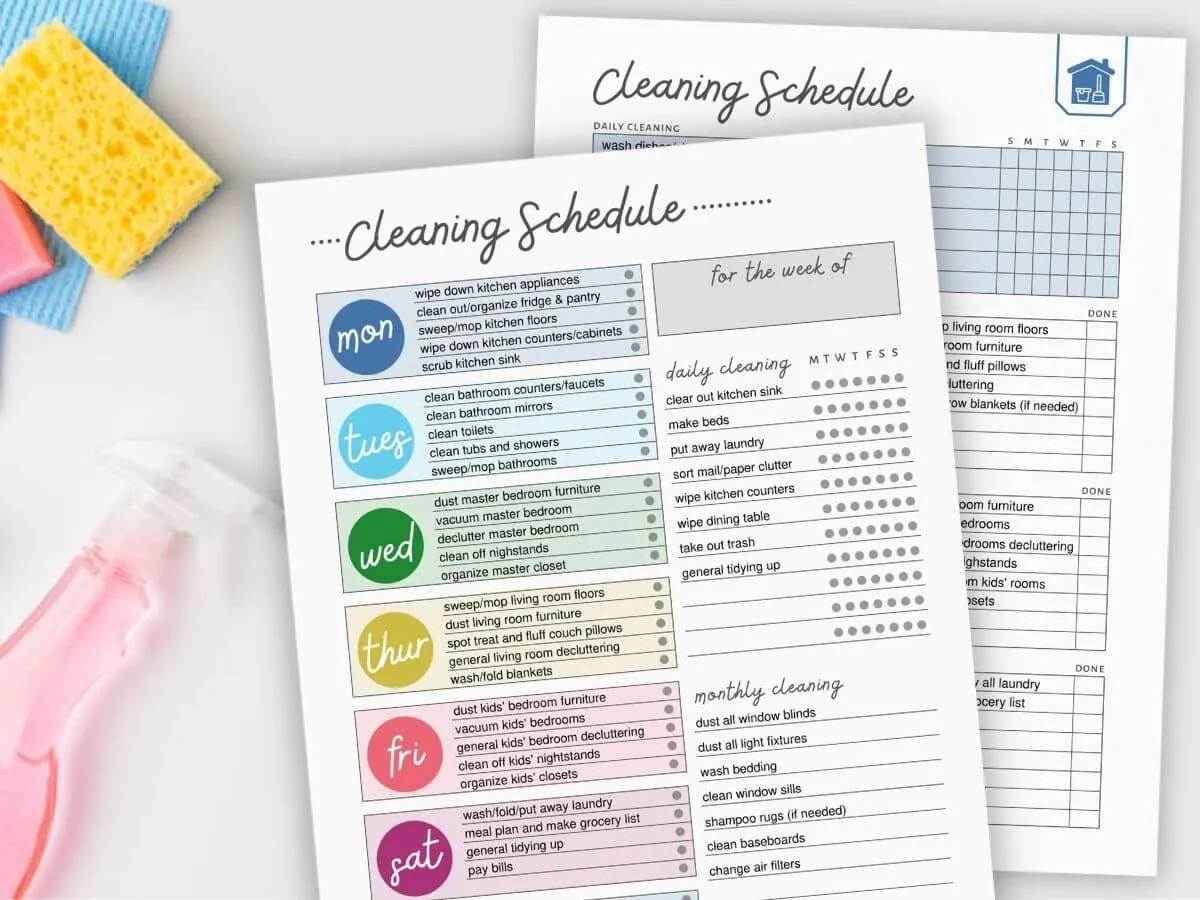

Developing a Cleaning Schedule and Log

Consistency is ensured through a documented Cleaning Schedule. This master plan should detail what needs to be cleaned, how it should be cleaned, who is responsible, and when (daily, weekly, monthly). A complementary Cleaning Log provides verifiable proof that tasks were completed, which is crucial for internal audits and health inspections.

Best Practices and Safety Considerations

- Use the Right Tools: Color-coded brushes and cloths (e.g., red for raw meat equipment, blue for general surfaces) prevent cross-contamination.

- Follow Manufacturer Instructions (MFI): Always consult the equipment manual for specific disassembly, cleaning, and compatibility guidelines.

- Focus on High-Touch & High-Risk Areas: Pay extra attention to handles, buttons, blades, and seals where debris accumulates.

- Employee Training: Comprehensive, ongoing training is vital. Staff must understand the "why" behind procedures.

- Personal Protective Equipment (PPE): Gloves, aprons, and eye protection should be worn when handling chemicals or cleaning sharp equipment.

Conclusion

Cleaning food preparation equipment is a scientific and systematic discipline integral to successful food handling. It is a proactive investment that pays dividends in food safety, operational efficiency, regulatory compliance, and equipment lifespan. By implementing a rigorous, documented cleaning and sanitizing program tailored to specific equipment and adhering to core principles, food service operators create a foundation of safety and quality that protects both their customers and their business.