The food processing industry is under constant pressure to improve efficiency, ensure product consistency, and meet evolving consumer demands. One critical area where technological advancement plays a pivotal role is in food forming equipment—the machinery responsible for shaping products like nuggets, patties, dough, and confectionery. This analysis explores the financial and operational implications of upgrading such equipment, weighing the initial investment against the long-term benefits.

Initial Investment and Costs

Upgrading food forming machinery involves significant capital expenditure. The costs are multifaceted and must be carefully itemized to form a complete financial picture.

1. Capital Expenditure (CapEx)

This is the direct cost of purchasing new equipment. Advanced forming machines with higher automation, precision, and speed command a premium. Depending on the technology—such as extrusion, molding, or sheeting systems—prices can range from $100,000 to over $1 million.

2. Installation and Integration Costs

New machinery often requires facility modifications, utility upgrades (electrical, pneumatic), and integration with existing production lines (e.g., conveyors, packaging systems). These costs can add 15-25% to the base equipment price.

3. Training and Transition

Operators and maintenance staff require training on new systems. Additionally, there may be a period of reduced output during installation and commissioning, leading to temporary production losses.

4. Financing Costs

If the purchase is financed through loans or leases, interest and fees contribute to the total cost of ownership.

| Cost Category | Estimated Range | Notes |

|---|---|---|

| Equipment Purchase | $250,000 - $500,000 | Varies by capacity and automation level |

| Installation & Integration | $37,500 - $125,000 | 15-25% of equipment cost |

| Training & Transition Loss | $10,000 - $30,000 | One-time costs for staff and downtime |

| Annual Maintenance Contract | $12,500 - $25,000 | ~5% of equipment cost per year |

| Total Initial Outlay | $310,000 - $680,000 | First-year investment |

Quantifiable Benefits and Returns

The justification for an upgrade lies in the tangible and intangible benefits that accrue over the equipment's lifespan, typically 10-15 years.

1. Increased Production Efficiency and Output

Modern formers operate at higher speeds with faster changeovers. This can increase line throughput by 20-40%, allowing more product to be made in the same time, thus reducing the cost per unit.

Example: A line producing 1,000 kg/hour upgraded to 1,300 kg/hour generates 300 kg of additional product per hour. At a profit margin of $2/kg, this creates $600 of extra margin per operating hour.

2. Reduced Material Waste and Improved Yield

Precision forming minimizes product giveaway and trim loss. Advanced systems offer better control over weight and shape, ensuring compliance with standards and reducing raw material overuse.

3. Labor Cost Savings

Automation reduces the number of operators required for manual handling, inspection, and adjustment. One automated line might replace several semi-automatic machines and their operators.

4. Enhanced Product Quality and Consistency

Consistent forming improves product appearance, texture, and cooking performance, leading to higher customer satisfaction, fewer rejections, and potentially a stronger brand reputation allowing for premium pricing.

5. Lower Maintenance and Energy Costs

Newer machines often have more efficient drives, better seals, and smarter diagnostics, leading to lower energy consumption (10-20% savings) and reduced unplanned downtime.

| Benefit Stream | Annual Savings/Gain | Calculation Basis |

|---|---|---|

| Increased Throughput | $180,000 | 300 kg/hr extra x $2/kg margin x 300 days x 8 hr/day |

| Material Waste Reduction | $45,000 | 2% yield improvement on $2.25M annual material cost |

| Labor Savings | $80,000 | Reduction of 1.5 FTE positions with burden |

| Energy & Maintenance | $15,000 | Reduced utility and repair costs |

| Total Annual Benefits | $320,000 | Sum of all quantifiable gains |

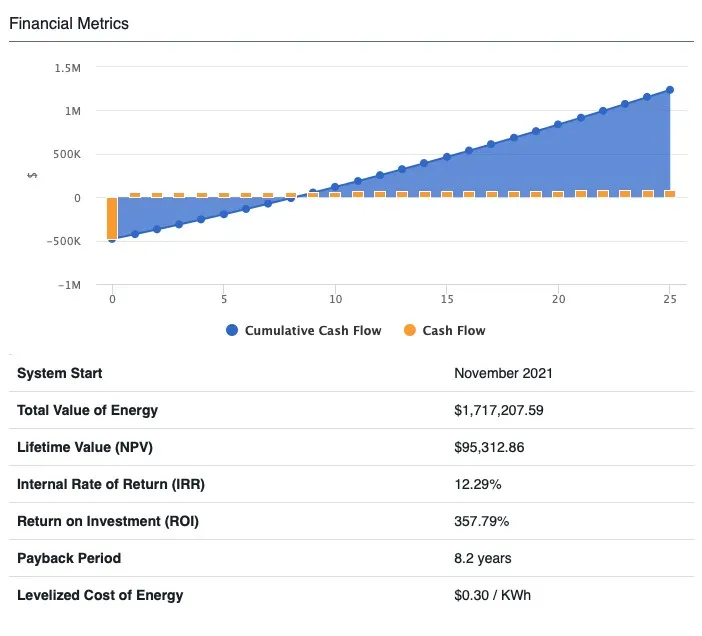

Financial Metrics and Decision Framework

To make an objective decision, companies employ standard financial analysis tools.

Payback Period

This is the time required for the cumulative benefits to equal the initial investment. Using the figures from our tables:

Payback Period = Total Initial Outlay / Total Annual Benefits

Using mid-range estimates: $495,000 / $320,000 ≈ 1.55 years.

A payback period under 3 years is generally considered excellent for capital equipment in the food industry.

Net Present Value (NPV)

NPV discounts future cash flows back to their present value, using a discount rate (e.g., company's cost of capital). A positive NPV indicates the project adds value.

Simplified NPV Insight: With benefits of $320,000/year for 10 years and a discount rate of 8%, the NPV would be significantly positive, strongly justifying the investment.

Return on Investment (ROI)

ROI measures the efficiency of the investment.

ROI = (Net Annual Benefits / Total Initial Cost) x 100

($320,000 / $495,000) x 100 ≈ 65% annual return on the invested capital.

Intangible and Strategic Benefits

Beyond the numbers, upgrades offer strategic advantages:

- Flexibility: Ability to produce new, complex product shapes to meet market trends.

- Compliance & Safety: Easier adherence to stringent food safety standards (e.g., hygienic design, traceability).

- Scalability: A platform for future expansion without major additional capital outlay.

- Employee Morale: Working with modern, reliable equipment can improve safety and job satisfaction.

Conclusion

The decision to upgrade food forming equipment is a strategic investment. While the upfront costs are substantial, a thorough cost-benefit analysis typically reveals a compelling financial case driven by increased efficiency, reduced waste, and lower operating costs. The payback period is often short, and the ROI high. Furthermore, the intangible benefits of improved quality, flexibility, and compliance secure long-term competitive advantage. For food processors aiming to thrive in a dynamic market, investing in modern forming technology is not merely an expense but a critical driver of sustainable profitability and growth.