In the food and beverage industry, maintaining impeccable hygiene is not just a best practice—it is a legal and ethical imperative. Food grade cleaning equipment forms the backbone of any effective sanitation program, designed specifically to prevent contamination, eliminate pathogens, and ensure product safety. Unlike general-purpose cleaning tools, food grade equipment is manufactured with materials and designs that meet stringent regulatory standards, ensuring they do not themselves become sources of chemical, physical, or biological hazards.

Why Food Grade Certification is Non-Negotiable

Food grade cleaning equipment is defined by its compliance with standards set by authorities such as the FDA (Food and Drug Administration) in the USA, the EFSA (European Food Safety Authority) in Europe, and other global bodies. These standards mandate that materials in contact with food surfaces must be non-toxic, non-absorbent, corrosion-resistant, and able to withstand repeated cleaning and sanitizing. The primary goal is to prevent the transfer of harmful substances or allergens into the food product.

Key Material Considerations

Common materials include high-grade stainless steel (AISI 300 series), certain plastics like polypropylene or HDPE that are certified for food contact, and silicone. These materials are chosen for their durability, smooth surfaces (free of pits or cracks where bacteria can hide), and resistance to harsh cleaning chemicals.

Core Categories of Food Grade Cleaning Equipment

The range of equipment is vast, tailored to different zones and tasks within a food handling environment.

1. Manual Cleaning Tools

These include brushes, scrapers, squeegees, and pads. They are often color-coded (e.g., red for raw meat areas, blue for ready-to-eat zones) to prevent cross-contamination. Handles are designed for ergonomics and easy cleaning.

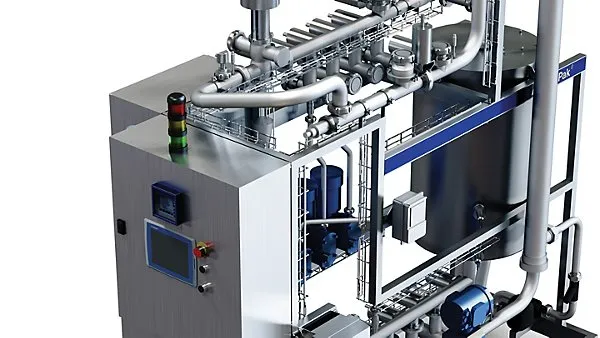

2. Cleaning and Sanitizing Systems

This encompasses foamers, central high-pressure/low-pressure systems, and Clean-in-Place (CIP) systems. CIP systems are automated and are critical for cleaning the interiors of tanks, pipelines, and vessels without disassembly.

3. Sanitation Station Equipment

Foot-operated or sensor-activated sinks, boot washers, hand sanitizing stations, and dedicated storage racks for air-drying tools fall under this category. They ensure personnel hygiene and proper tool maintenance.

Selection Criteria and Best Practices

Choosing the right equipment involves a thorough risk assessment of the facility.

| Factor | Consideration | Example / Standard |

|---|---|---|

| Material Compliance | Must be certified for food contact and suitable for the cleaning chemicals used. | FDA 21 CFR, EU Regulation 1935/2004 |

| Hygienic Design | No dead spaces, crevices, or hollow parts where biofilms can form. Easy to disassemble and clean. | EHEDG (European Hygienic Engineering & Design Group) guidelines |

| Durability & Safety | Resistance to physical damage and corrosion. Non-slip handles for wet conditions. | Stainless steel grade 316 for high-chloride environments |

| Zone Compatibility | Equipment must be designated for specific risk areas (e.g., raw vs. cooked) to prevent allergen cross-contact. | Color-coding system implemented facility-wide |

| Validation & Verification | Equipment should facilitate and not hinder cleaning validation protocols and microbial testing. | Surface swab testing after cleaning to verify efficacy |

Implementing a Master Sanitation Schedule

Equipment must be integrated into a documented Master Sanitation Schedule (MSS) that specifies what is to be cleaned, with which tools and chemicals, how often, and by whom. This procedural approach ensures consistency and accountability.

The Cost of Non-Compliance: Risks of Inadequate Equipment

Using non-compliant or poorly designed cleaning tools carries severe consequences. These include product recalls due to contamination, legal action and fines from regulatory bodies, damage to brand reputation, and most importantly, risks to consumer health from foodborne illnesses like Listeria or E. coli. Investing in proper food grade equipment is ultimately a cost-saving measure that protects both public health and the business's viability.

Future Trends: Automation and Smart Technology

The future of food grade cleaning is moving towards greater automation and data integration. Sensors on equipment can monitor usage, chemical concentration, and water temperature. IoT-enabled devices can log cleaning cycles directly into digital compliance records, providing real-time data for audits and predictive maintenance, thereby enhancing traceability and efficiency.