In the competitive food industry, effective packaging is crucial for success. For small businesses, finding the right packaging solution can be challenging due to budget constraints and space limitations. However, investing in appropriate food packaging machines can significantly enhance efficiency, product quality, and brand perception. This guide explores the various types of packaging machines suitable for small-scale operations, their benefits, and how to select the right equipment for your specific needs.

A small food business owner operating a tabletop vacuum sealer for artisanal products

A small food business owner operating a tabletop vacuum sealer for artisanal products

Why Small Food Businesses Need Packaging Machines

Many small food entrepreneurs start with manual packaging methods, but as demand grows, this approach becomes inefficient and unsustainable. Packaging machines offer numerous advantages that can help small businesses scale effectively while maintaining quality standards.

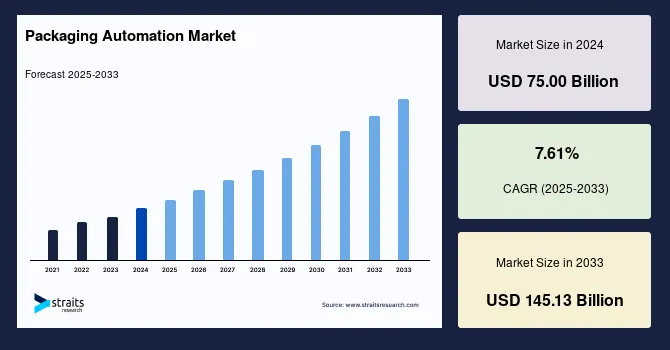

Key Benefits of Packaging Automation for Small Operations

Implementing even basic packaging automation provides significant advantages for growing food businesses:

- Increased Efficiency: Machines package products much faster than manual methods, allowing you to handle larger orders without increasing labor costs disproportionately.

- Consistency: Automated packaging ensures every product looks professional and identical, enhancing brand perception.

- Extended Shelf Life: Many machines create airtight seals that protect against oxygen, moisture, and contaminants, preserving freshness longer.

- Cost Savings: While there's an initial investment, packaging machines reduce material waste and labor costs over time.

- Regulatory Compliance: Proper packaging helps meet food safety standards and labeling requirements.

Side-by-side comparison showing the professional appearance of machine-packaged products versus hand-packaged items

Side-by-side comparison showing the professional appearance of machine-packaged products versus hand-packaged items

Types of Food Packaging Machines for Small Businesses

Various packaging machines cater to different needs, products, and budgets. Understanding the options available helps you make an informed decision for your specific operation.

Vacuum Sealers

Vacuum sealers remove air from packages before sealing, significantly extending the shelf life of perishable products. They're ideal for meats, cheeses, prepared meals, and dried goods.

Types of Vacuum Sealers:

- Chamber Vacuum Sealers: Best for liquids and moist products, though typically more expensive

- External Vacuum Sealers: More affordable and suitable for drier products

- Handheld Vacuum Sealers: Portable options for very small operations or occasional use

A compact chamber vacuum sealer suitable for small batch operations

A compact chamber vacuum sealer suitable for small batch operations

Heat Sealers

Heat sealers use controlled temperatures to create airtight seals on plastic bags or pouches. They're versatile, relatively inexpensive, and work well for snacks, baked goods, and frozen items.

Labeling Machines

While not strictly packaging machines, labelers ensure compliance with regulatory requirements and enhance brand presentation. Semi-automatic models are affordable and significantly faster than hand labeling.

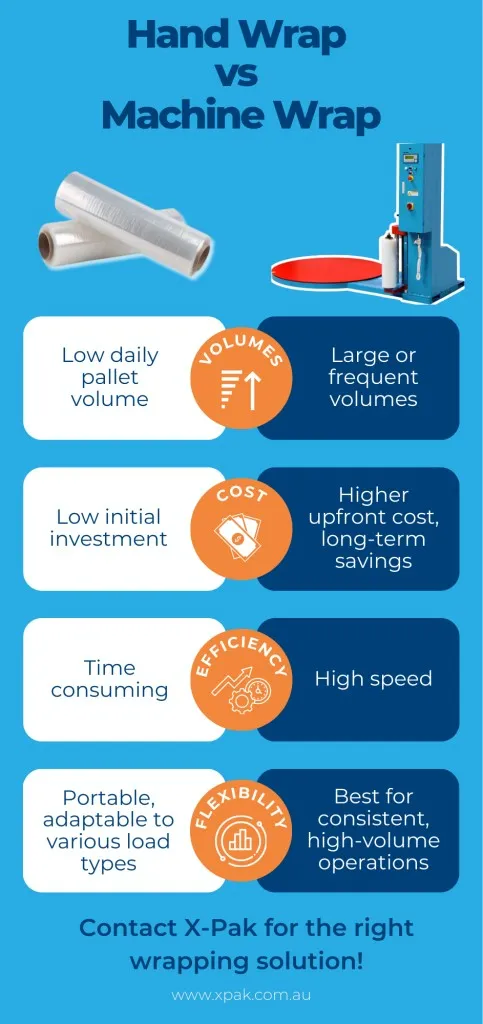

Shrink Wrap Machines

These machines use heat to shrink plastic film tightly around products. They're excellent for multi-packs, irregular shapes, and providing tamper-evident packaging.

A compact shrink wrap tunnel suitable for small business applications

A compact shrink wrap tunnel suitable for small business applications

Form-Fill-Seal Machines

These advanced systems form packages from roll stock, fill them with product, and seal them in one continuous operation. While more expensive, they offer maximum efficiency for high-volume products.

Factors to Consider When Choosing a Packaging Machine

Selecting the right equipment requires careful consideration of multiple factors to ensure it meets your current needs while allowing room for growth.

| Factor | Considerations | Questions to Ask |

|---|---|---|

| Product Type | Liquid, solid, fragile, powder | What consistency is my product? Does it require special handling? |

| Production Volume | Current and projected output | How many units do I package per hour/day/week? |

| Available Space | Footprint of equipment | How much space can I dedicate to packaging operations? |

| Budget | Initial cost, operating expenses, ROI | What is my total budget including accessories and maintenance? |

| Packaging Materials | Compatibility with various films, bags | What materials do I want to use? Are they compatible? |

| Ease of Use | Training requirements, complexity | How technically skilled are my employees? |

An efficiently organized small business packaging area with multiple compact machines

An efficiently organized small business packaging area with multiple compact machines

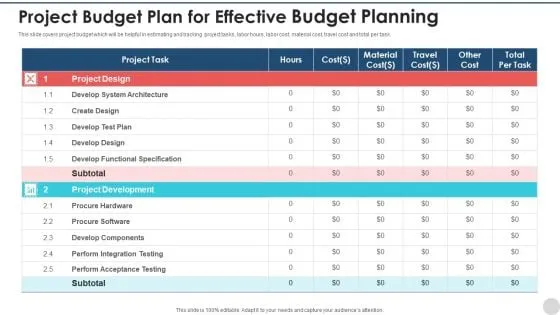

Budget Considerations for Small Businesses

Cost is often the primary concern for small businesses when considering packaging automation. Understanding the full financial picture helps make a sound investment decision.

Initial Investment vs. Long-Term Savings

While packaging machines require upfront investment, they typically generate savings through:

- Reduced labor costs (fewer hours spent on manual packaging)

- Decreased material waste (precise sealing minimizes failed packages)

- Longer product shelf life (reducing spoilage and returns)

- Premium pricing potential (professional appearance justifies higher prices)

Cost Range for Small Business Packaging Equipment

Packaging machines suitable for small operations vary widely in price:

- Basic heat sealers: $100 - $500

- External vacuum sealers: $200 - $800

- Chamber vacuum sealers: $800 - $3,000

- Semi-automatic form-fill-seal machines: $3,000 - $10,000

- Labeling machines: $500 - $2,500

A small business owner reviewing equipment options and costs on a laptop

A small business owner reviewing equipment options and costs on a laptop

Space-Saving Solutions for Limited Areas

Many small food businesses operate in compact kitchens or shared facilities where space is at a premium. Fortunately, manufacturers now offer numerous space-efficient packaging solutions.

Compact and Benchtop Models

Most equipment designed for small businesses features a small footprint and can be placed on standard countertops or mobile carts. Some machines offer dual functionality, combining multiple packaging processes in one unit.

Storage and Mobility Considerations

When space is limited, consider equipment that can be easily stored when not in use. Some options include:

- Foldable or collapsible machines

- Units with built-in storage for accessories

- Mobile carts that allow equipment to be moved as needed

Maintenance and Operational Tips

Proper maintenance ensures your packaging equipment operates efficiently and lasts longer, protecting your investment.

Routine Maintenance Tasks

Regular care varies by machine type but typically includes:

- Daily cleaning of sealing elements

- Regular inspection of moving parts

- Lubrication as recommended by the manufacturer

- Calibration checks to ensure proper sealing temperatures and pressures

Proper cleaning and maintenance of a food packaging machine

Proper cleaning and maintenance of a food packaging machine

Troubleshooting Common Issues

Small business owners should familiarize themselves with common problems such as incomplete seals, film jams, or inconsistent packaging. Many issues can be resolved with simple adjustments rather than requiring professional service.

Scaling With Your Business

The right packaging equipment should accommodate your current needs while allowing for future growth without requiring complete replacement.

Modular and Upgradeable Systems

Some manufacturers offer modular systems that can be expanded with additional features or higher capacity components as your business grows. This approach spreads investment costs over time while preventing equipment obsolescence.

When to Upgrade Equipment

Signs that it might be time to upgrade your packaging equipment include:

- Consistently unable to meet packaging demands

- Frequent breakdowns and maintenance issues

- New product lines requiring different packaging formats

- Substantial growth in order volume

A small food business that has expanded with the help of efficient packaging systems

A small food business that has expanded with the help of efficient packaging systems

Conclusion

Investing in appropriate food packaging machines is a strategic decision that can propel a small food business toward growth and success. By carefully assessing your specific needs, production requirements, and budget constraints, you can select equipment that enhances efficiency, improves product presentation, extends shelf life, and ultimately increases profitability. Start with the most critical packaging need for your operation, and gradually expand your capabilities as your business grows. The right packaging solution not only protects your products but also communicates quality and professionalism to your customers, helping your small business stand out in a competitive market.

Small business food packaging machines enhance efficiency, reduce costs, and improve product shelf life. This guide explores various packaging equipment options suitable for small-scale operations, including vacuum sealers, heat sealers, and labeling machines. Learn how to select the right machine based on your product type, budget, and space constraints while considering future growth potential.