The confectionery industry stands at the precipice of a technological revolution, driven by evolving consumer demands, sustainability concerns, and rapid advancements in automation and data analytics. The machinery that produces our favorite sweets—from chocolate bars to gummy bears—is undergoing a profound transformation. This article explores the key trends and innovations shaping the future of confectionery machinery, painting a picture of a more efficient, sustainable, and customizable manufacturing landscape.

1. The Rise of Smart Factories and Industry 4.0

The integration of Industry 4.0 principles is arguably the most significant trend impacting confectionery machinery. The concept of the "smart factory," where machines are interconnected and communicate with each other, is becoming a reality. This involves the deployment of Internet of Things (IoT) sensors on equipment like mixers, depositors, and wrappers.

These sensors collect real-time data on parameters such as temperature, viscosity, motor speed, and energy consumption. This data is then analyzed by AI-powered systems to:

- Predict Maintenance: Identify potential equipment failures before they occur, minimizing unplanned downtime.

- Optimize Production: Automatically adjust machine settings for maximum efficiency and consistent product quality.

- Enhance Traceability: Track every ingredient and finished product through the entire supply chain.

| Technology | Application in Confectionery Machinery | Benefit |

|---|---|---|

| Internet of Things (IoT) | Sensors on tempering units, extruders, and packaging machines | Real-time monitoring and data collection |

| Artificial Intelligence (AI) | Vision systems for quality control and predictive maintenance algorithms | Improved quality and reduced downtime |

| Big Data Analytics | Analysis of production data to optimize recipes and energy usage | Increased efficiency and cost savings |

| Digital Twins | Virtual replicas of production lines for simulation and testing | Faster innovation and risk-free process optimization |

2. Sustainability as a Core Driver of Innovation

Consumer and regulatory pressure for environmentally friendly practices is pushing manufacturers to invest in sustainable machinery. Future confectionery equipment will be designed with a circular economy in mind.

2.1 Energy and Water Efficiency

New generations of ovens, coolers, and cleaning-in-place (CIP) systems are being engineered to consume significantly less energy and water. Heat recovery systems, for instance, can capture waste heat from one part of the process to use in another.

2.2 Reduction of Food and Packaging Waste

High-precision depositing and molding machines ensure minimal product giveaway and waste. Furthermore, machinery is adapting to handle alternative, biodegradable, and recyclable packaging materials. Innovations in flexible packaging machinery are crucial for meeting sustainability goals without compromising product shelf life.

3. Hyper-Personalization and Flexibility

The era of mass production of a single product is giving way to demand for personalized and limited-edition confectionery. Machinery must become more agile to accommodate this shift.

- Modular Design: Production lines will be composed of interchangeable modules that can be quickly reconfigured for different products, from hard candies to chocolate figures.

- Digital Printing: Edible ink printers integrated into production lines can apply customized designs, messages, or images directly onto chocolates and candies, enabling on-demand personalization.

- Small-Batch Capability: Flexible machinery will allow for economical production of small batches, catering to niche markets and allowing for rapid prototyping of new recipes.

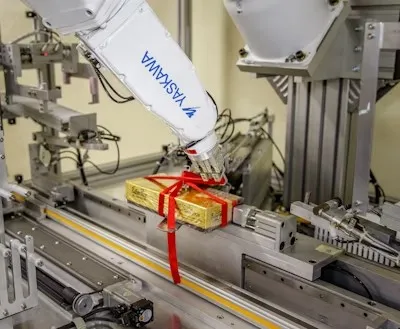

4. Advanced Robotics and Collaborative Automation

Robotics are moving beyond simple pick-and-place tasks. Advanced vision-guided robots are now capable of performing delicate operations like decorating cakes, assembling complex confectionery products, and performing final quality inspections with superhuman accuracy and consistency.

| Era | Robotic Function | Example |

|---|---|---|

| Past | Simple, repetitive tasks | Palletizing finished boxes |

| Present | Complex handling and packaging | Picking and placing fragile chocolates |

| Future | Collaborative and cognitive tasks | Working alongside humans for assembly and adaptive quality control |

Collaborative robots, or "cobots," designed to work safely alongside human operators, will become more prevalent. They can assist with tasks that require human dexterity and machine precision, such as hand-finishing premium products.

5. Enhanced Food Safety and Hygiene by Design

Food safety is non-negotiable. Future machinery will incorporate hygienic design principles from the ground up. This includes the use of easy-to-clean, corrosion-resistant materials, seamless surfaces to prevent bacterial harborage, and automated cleaning systems that ensure thorough sanitation with minimal chemical and water usage. X-ray and metal detection systems will become more sophisticated and integrated directly into the production flow.

Conclusion

The future of confectionery machinery is intelligent, sustainable, and incredibly flexible. The convergence of IoT, AI, and advanced robotics is creating a new paradigm for manufacturing that prioritizes efficiency, customization, and environmental responsibility. As these technologies mature and become more accessible, we can expect confectionery producers to deliver higher quality, more innovative, and more personalized products to consumers worldwide, all while reducing their environmental footprint. The factory of the future will not just make candy; it will craft experiences with precision and purpose.