The food packaging industry is undergoing a significant transformation driven by technological advancements, changing consumer preferences, and increasing environmental concerns. Modern packaging machinery is becoming smarter, more efficient, and more sustainable than ever before. This article explores the key trends shaping the future of food packaging machinery and their implications for manufacturers and consumers alike.

Smart Packaging and Industry 4.0 Integration

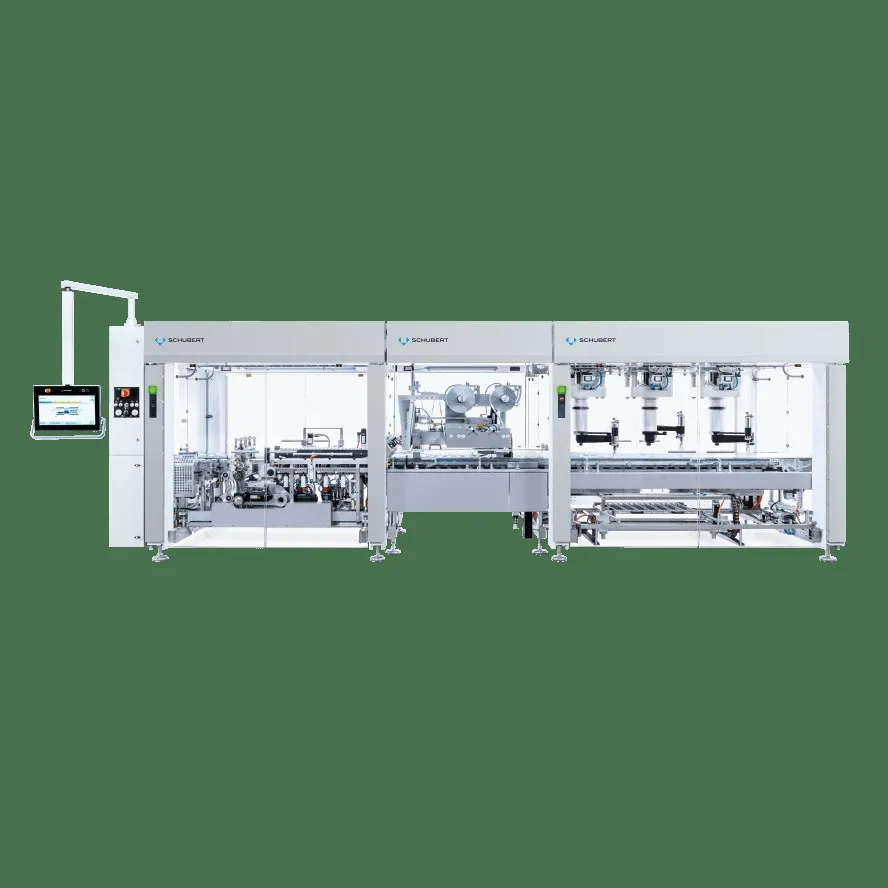

The integration of Industry 4.0 technologies is revolutionizing food packaging operations. Smart packaging machinery equipped with IoT sensors, artificial intelligence, and real-time data analytics is becoming the new standard in modern food processing facilities.

These intelligent systems enable predictive maintenance, reducing downtime and increasing overall equipment effectiveness. Manufacturers can monitor machine performance remotely, anticipate potential failures, and optimize production schedules based on real-time data. The connectivity between different packaging lines and enterprise resource planning systems creates a seamless flow of information throughout the manufacturing ecosystem.

Key Benefits of Smart Packaging Systems

- Real-time quality control and defect detection

- Predictive maintenance capabilities

- Reduced energy consumption through optimized operations

- Enhanced traceability throughout the supply chain

Sustainable Packaging Solutions

Sustainability has become a critical focus in food packaging, with machinery manufacturers developing innovative solutions to reduce environmental impact. The shift toward biodegradable materials, reduced packaging weight, and circular economy principles is driving new machinery designs and capabilities.

Modern packaging machines are being designed to handle a wider variety of sustainable materials, including compostable plastics, paper-based alternatives, and edible packaging. Advanced sealing technologies ensure that sustainable materials provide the same level of protection as traditional options while minimizing environmental footprint.

| Material Type | Current Adoption Rate | Projected Growth (2024-2027) | Key Applications |

|---|---|---|---|

| Biodegradable Plastics | 35% | 45% | Fresh produce, baked goods |

| Paper-based Packaging | 28% | 38% | Dry foods, frozen products |

| Edible Packaging | 5% | 15% | Single-serve condiments, supplements |

| Recycled Materials | 42% | 55% | Beverage containers, snack packaging |

Robotics and Automation Advancements

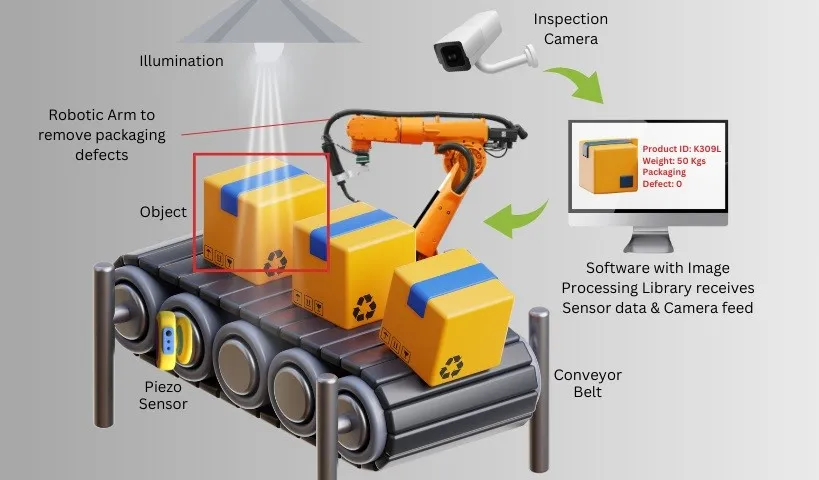

Robotic systems are becoming increasingly sophisticated in food packaging applications. Collaborative robots (cobots) work alongside human operators to enhance productivity while maintaining flexibility in packaging operations.

Advanced vision systems and machine learning algorithms enable robots to handle delicate food items with precision, adapt to varying product sizes, and perform complex packaging tasks. The integration of robotics has significantly improved packaging speed, accuracy, and consistency while reducing labor costs and minimizing human error.

Robotic Applications in Food Packaging

- Primary packaging: Pick-and-place, filling, and sealing operations

- Secondary packaging: Case packing and palletizing

- Quality inspection: Visual defect detection and weight verification

- Flexible packaging: Adapting to various package shapes and sizes

Advanced Aseptic Packaging Technologies

Aseptic packaging continues to evolve with new technologies that extend shelf life while maintaining nutritional quality and flavor. Modern aseptic packaging machines incorporate advanced sterilization methods and contamination prevention systems.

Innovations in aseptic processing include low-temperature sterilization techniques, improved package integrity testing, and enhanced clean-in-place systems. These advancements enable manufacturers to package a wider range of products aseptically, including particulate foods and sensitive nutritional formulations.

| Technology | Sterilization Method | Suitable Products | Shelf Life Extension |

|---|---|---|---|

| Traditional Thermal | High-temperature steam | Liquid dairy, juices | 6-12 months |

| UHT Processing | Ultra-high temperature | Milk, cream, soups | 9-12 months |

| HPP Packaging | High-pressure processing | Ready meals, guacamole | 3-6 months |

| Electron Beam | Radiation sterilization | Spices, medical nutrition | 12-24 months |

Flexible and Adaptive Packaging Systems

The demand for product variety and shorter production runs is driving the development of more flexible packaging machinery. Modern systems can quickly change between different package formats, sizes, and materials with minimal downtime.

Adaptive packaging systems utilize digital twins and simulation software to optimize changeover processes before implementation. This flexibility allows manufacturers to respond quickly to market trends and consumer preferences while maintaining efficient production operations.

Enhanced Food Safety and Traceability

Food safety remains a top priority, with packaging machinery incorporating advanced features to ensure product integrity. Blockchain technology, QR codes, and RFID tags are being integrated into packaging lines to provide complete traceability from farm to fork.

Modern inspection systems can detect microscopic contaminants, verify label accuracy, and ensure proper sealing. These technologies not only enhance food safety but also build consumer trust through transparency and quality assurance.

Traceability Technologies in Packaging

- Blockchain integration for supply chain transparency

- Smart labels with temperature and freshness indicators

- Automated recall management systems

- Real-time production monitoring and documentation

Conclusion

The food packaging machinery industry is at the forefront of technological innovation, driven by the need for efficiency, sustainability, and safety. As these trends continue to evolve, manufacturers who embrace smart technologies, sustainable practices, and flexible systems will be well-positioned to meet the changing demands of the global food market. The future of food packaging lies in intelligent, adaptable, and environmentally responsible solutions that benefit both businesses and consumers.