The modern dairy industry relies on sophisticated, high-efficiency processing equipment to transform raw milk into a wide variety of safe, high-quality products. From basic pasteurization to complex cheese or yogurt production, each step requires specialized machinery designed for hygiene, precision, and energy efficiency. Understanding the core components of this equipment is essential for optimizing production lines, ensuring product safety, and maintaining profitability in a competitive market.

1. Separation and Standardization Systems

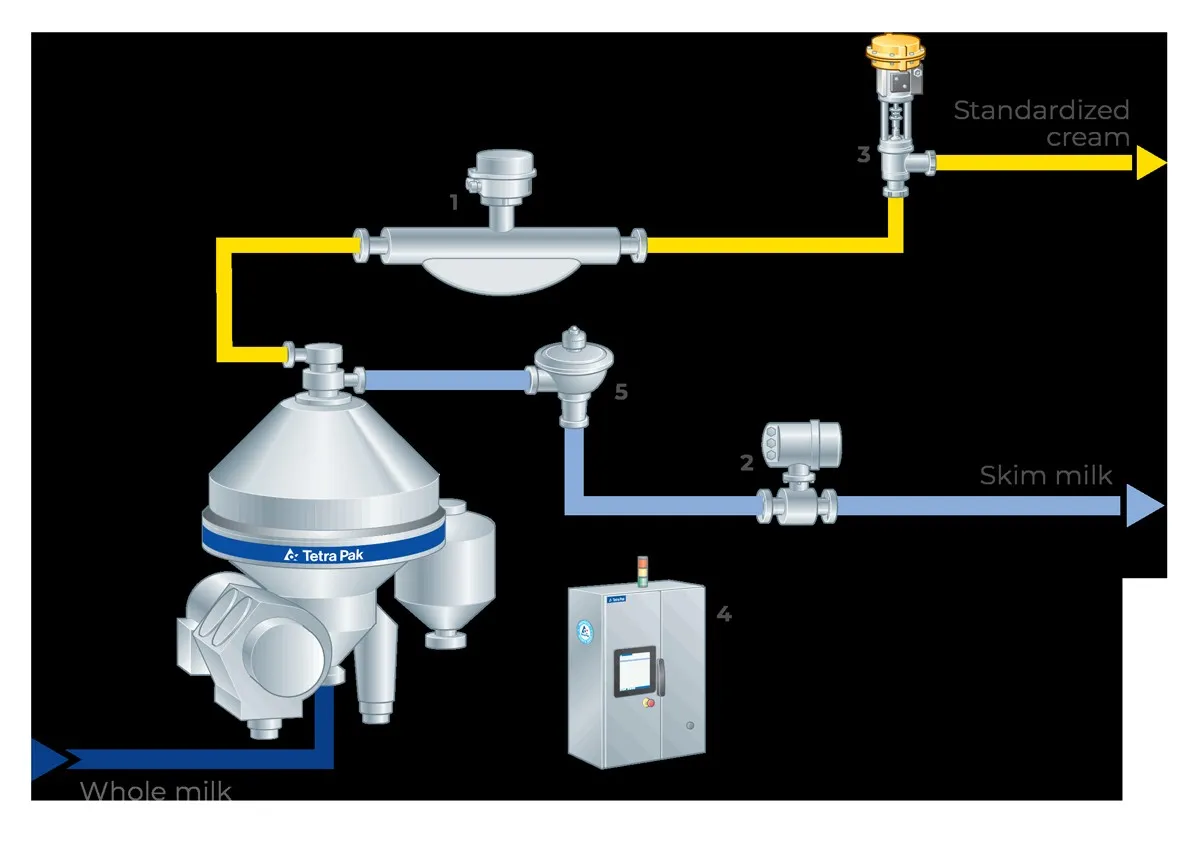

The initial stage of dairy processing often involves separating milk into its constituent parts: cream and skim milk. This is primarily achieved using centrifuges.

Centrifugal Separators: These high-speed rotating machines use centrifugal force to separate denser skim milk from lighter fat globules (cream). Modern separators are highly efficient, allowing for precise fat content adjustment—a process known as standardization. This ensures consistent product composition, whether for whole milk, skim milk, or cream with specific fat percentages.

Milk Clarifiers: Similar in design to separators, clarifiers remove solid impurities like somatic cells and sediment from raw milk, improving purity and extending the shelf life of downstream equipment.

2. Heat Treatment and Pasteurization Equipment

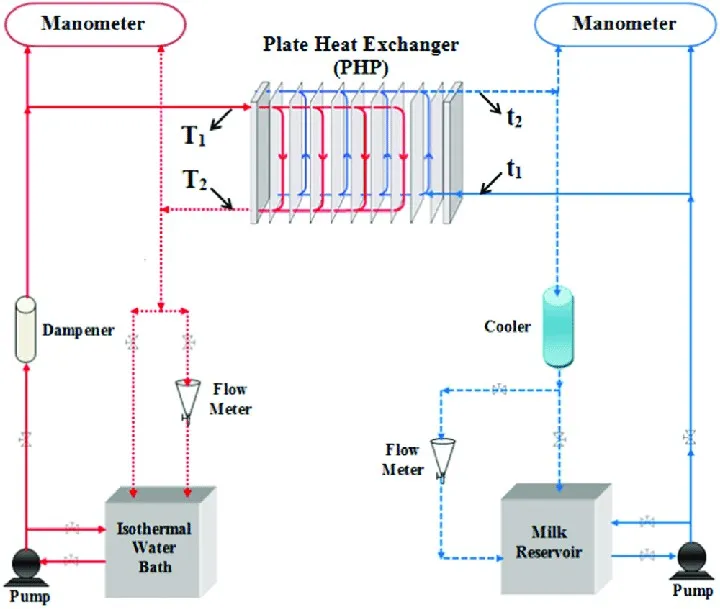

Heat treatment is critical for food safety, destroying pathogenic microorganisms. Pasteurization is the most common method.

Plate Heat Exchangers (PHEs): The workhorse of dairy pasteurization. PHEs consist of corrugated metal plates stacked together, creating alternating channels for hot water/steam and milk. They enable rapid, energy-efficient heating and cooling. Key types include:

| Pasteurization Type | Typical Temperature/Time | Primary Application |

|---|---|---|

| HTST (High-Temperature Short-Time) | 72°C for 15 seconds | Fluid milk, cream |

| UHT (Ultra-High Temperature) | 135-150°C for 1-4 seconds | Long-life milk, dairy drinks |

| Batch/LTLT (Low-Temperature Long-Time) | 63°C for 30 minutes | Specialty cheeses, cultured products |

Tubular & Scraped-Surface Heat Exchangers: Used for more viscous products (e.g., yogurt, custard) or those containing particulates, where plates would clog.

3. Homogenization Units

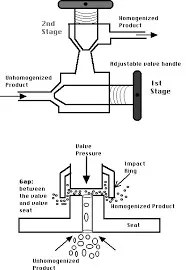

Homogenization prevents cream separation and ensures a uniform texture by reducing the size of fat globules in milk.

High-Pressure Homogenizers: These force milk under high pressure (typically 100-250 bar) through a tiny, specially designed valve or gap. The intense shear and cavitation forces break down fat globules into smaller, uniformly sized particles that remain dispersed throughout the product. This results in a smoother mouthfeel, whiter color, and improved stability.

4. Evaporation and Drying Systems

For producing concentrated and powdered dairy products like milk powder, whey powder, or condensed milk.

Evaporators: Multi-effect falling film evaporators are standard. They use steam energy efficiently across multiple stages ("effects") to remove water at low temperatures, preserving product quality.

Spray Dryers: Concentrated milk is atomized into a hot air chamber in fine droplets. The water evaporates instantly, leaving behind dry powder particles. Integrated fluidized beds provide secondary drying and cooling for better powder properties.

5. Culturing and Fermentation Tanks

Essential for products like yogurt, cheese, and buttermilk.

Fermentation/Incubation Tanks: These are insulated, jacketed vats with precise temperature control systems. They are designed for hygienic processing, often with top-mounted agitators for gentle mixing. After inoculation with starter cultures, the milk is held at a specific temperature to allow controlled fermentation, developing flavor, texture, and acidity.

6. Filling and Packaging Machinery

The final step that ensures product integrity and shelf life.

Aseptic Filling Lines: For UHT products, these fillers operate in a sterile environment, packaging milk into pre-sterilized containers (e.g., cartons, bottles) without recontamination. This allows for shelf-stable products without refrigeration.

Gable-top & Bottle Fillers: For fresh pasteurized products. High-speed machines that fill, seal, and date-code containers with minimal exposure to air.

7. Automation and Process Control

The brain of the modern dairy plant, integrating all components.

Programmable Logic Controllers (PLCs) & SCADA Systems: These computerized systems monitor and control every parameter—temperature, pressure, flow rates, valve positions, and tank levels. They ensure consistent product quality, automate cleaning cycles (CIP), optimize energy use, and provide traceability data for every batch produced.

Sensors & Instrumentation: In-line sensors for fat, protein, moisture, and bacterial count provide real-time data for immediate process adjustment, moving beyond traditional lab testing.

Conclusion

Efficient dairy processing is a symphony of specialized equipment working in harmony. From the raw milk intake to the packaged product, each component—separators, heat exchangers, homogenizers, dryers, and intelligent control systems—plays a vital role in ensuring safety, maximizing yield, conserving energy, and meeting the highest quality standards. Continuous innovation in these components drives the dairy industry toward greater sustainability and capability to meet diverse consumer demands.