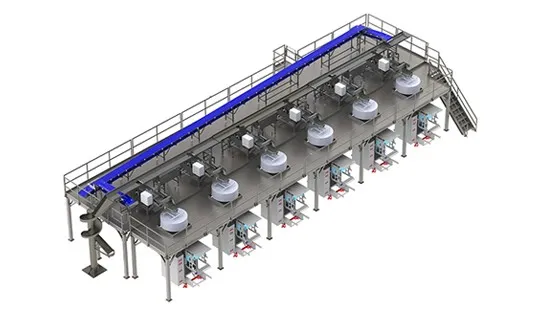

In the highly automated and regulated world of food production, the efficiency, safety, and quality of the entire process hinge on one critical component: the conveyor system. Food conveyor manufacturers are the specialized engineering partners who design, build, and integrate these vital lifelines of processing and packaging plants. Their work goes far beyond simply moving products from point A to point B; they create tailored solutions that ensure hygiene, prevent contamination, optimize throughput, and adapt to the diverse needs of everything from baked goods and snacks to meat, poultry, and ready meals.

Key Considerations When Selecting a Food Conveyor Manufacturer

Choosing the right manufacturer is a strategic decision. Not all conveyor builders possess the specific expertise required for food-grade applications. Key differentiators include a deep understanding of food safety standards, material science for food contact surfaces, and the ability to design for cleanability and sanitation.

1. Expertise in Food Safety and Compliance

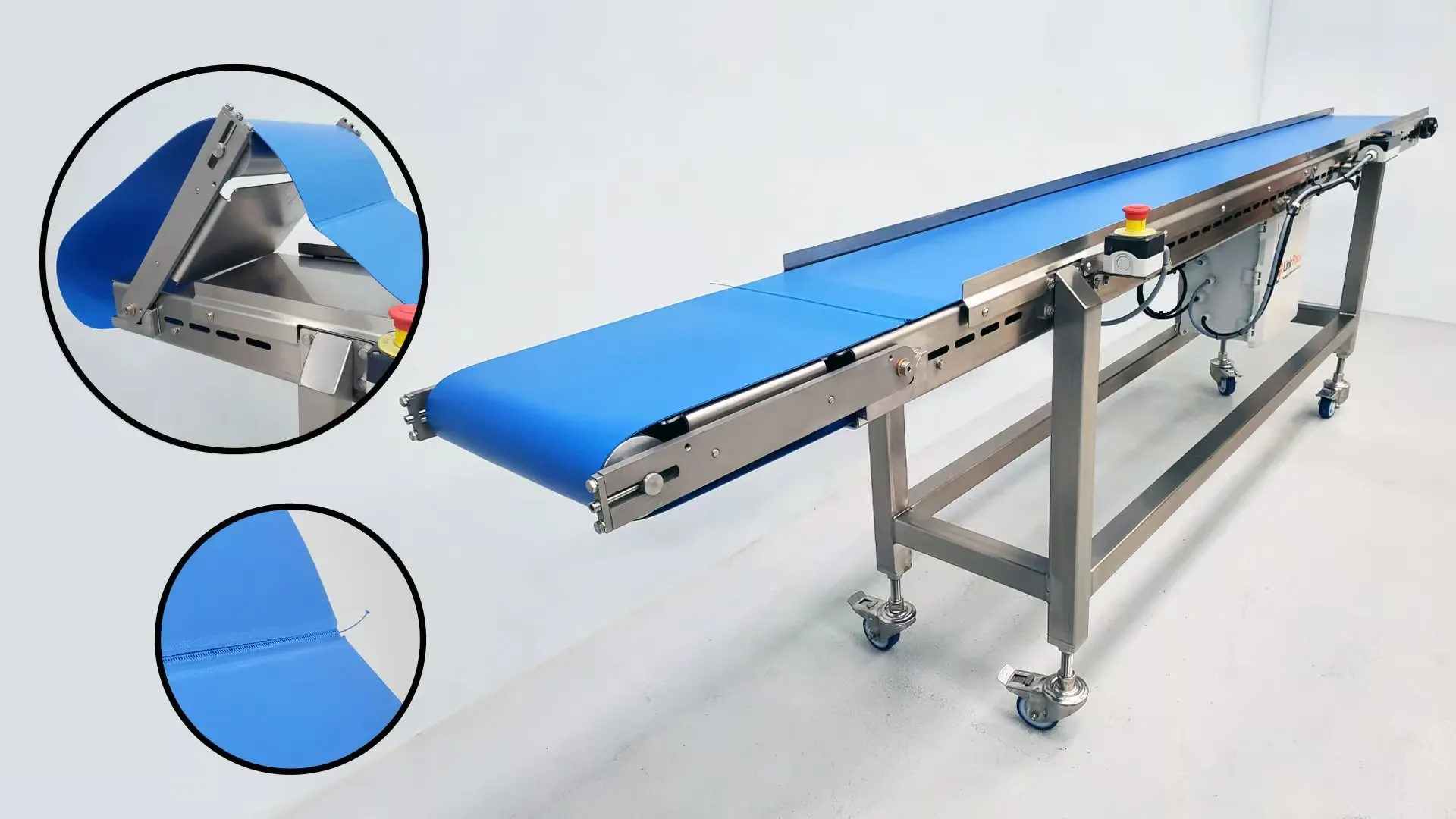

Top-tier manufacturers design systems that comply with stringent global standards such as FDA (USA), EHEDG (Europe), and 3-A Sanitary Standards. They utilize materials like stainless steel (grades 304 or 316), which are non-porous, corrosion-resistant, and easy to clean. Designs feature smooth surfaces, rounded corners, and minimal crevices to prevent bacterial harborage.

2. Custom Engineering and Flexibility

Every food product has unique handling requirements. Whether it's a gentle incline for delicate pastries, a vibratory conveyor for sorting vegetables, or a heavy-duty chain conveyor for canned goods, manufacturers must offer custom engineering. Modular designs that allow for future reconfiguration are a significant advantage.

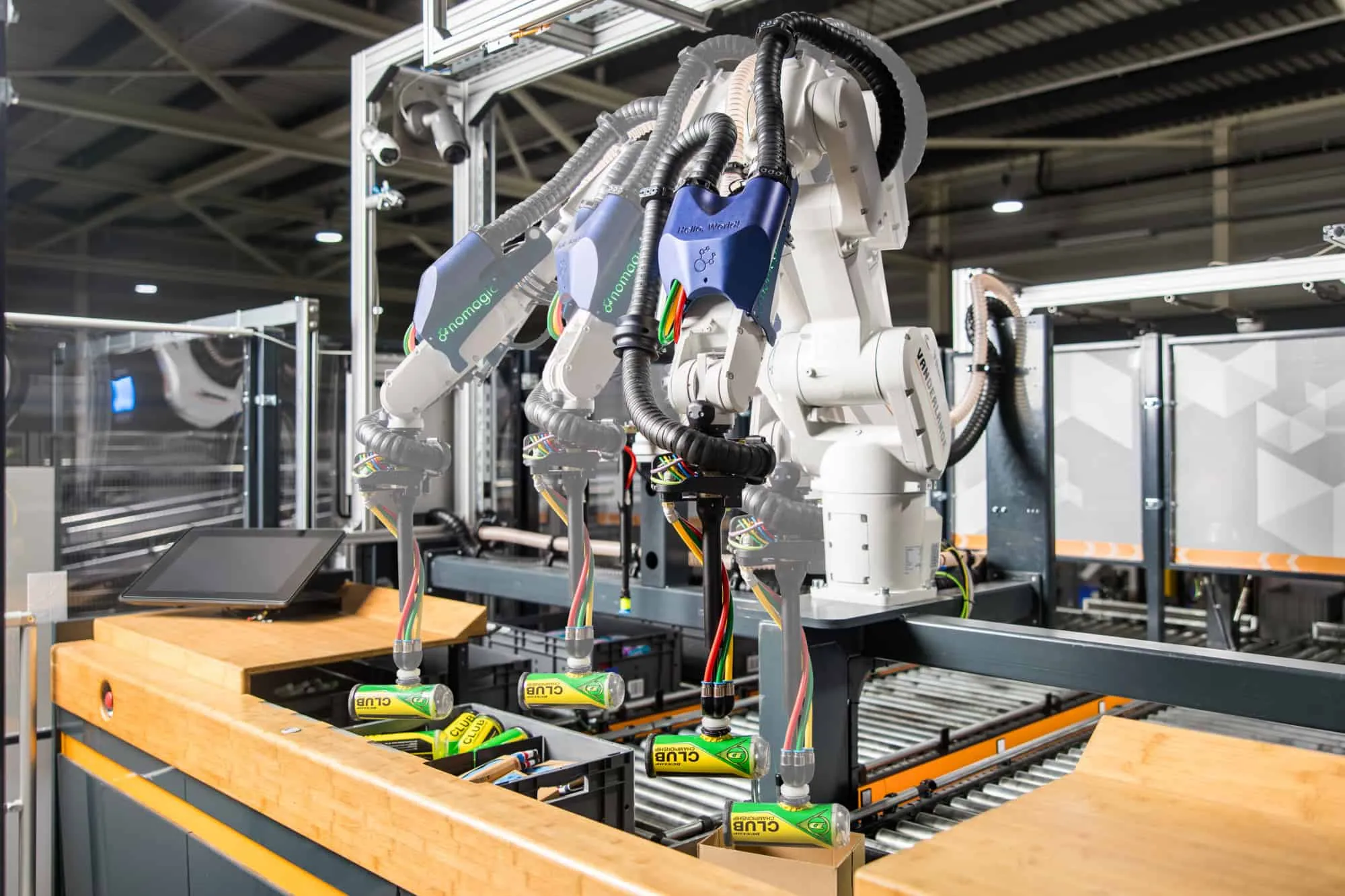

3. Technology and Innovation Integration

Leading manufacturers incorporate advanced technologies such as automated washdown systems, IoT sensors for predictive maintenance, and smart controls that integrate with plant-wide SCADA systems. This focus on innovation drives efficiency and reduces downtime.

Types of Conveyor Systems Offered by Specialized Manufacturers

The product portfolio of a comprehensive food conveyor manufacturer is diverse, addressing different stages of production.

| Conveyor Type | Primary Use Case | Key Features |

|---|---|---|

| Belt Conveyors | General transport of packaged goods, boxes, or certain bulk items. | Modular plastic, PU, or silicone belts; easy to clean; various inclines. |

| Modular Plastic Conveyors | Wet environments, cooling, washing, and inspection lines. | Open grid design for drainage, high chemical resistance, durable. |

| Vibratory Conveyors | Grading, sorting, and distributing bulk materials like nuts, fruits, or snacks. | Gentle product handling, efficient sorting action, sanitary design. |

| Screw (Auger) Conveyors | Moving powdered, granular, or semi-solid materials (flour, sugar, grains). | Enclosed tube prevents contamination, configurable for mixing or feeding. |

| Chain Conveyors | Heavy-duty applications like moving pallets, crates, or cans. | Extremely robust, high load capacity, suitable for harsh environments. |

The Partnership Process: From Concept to Operation

Working with a professional manufacturer follows a structured path:

Consultation and Needs Analysis

Engineers assess the product characteristics, flow rates, plant layout, and sanitation protocols.

Design and Engineering

Creation of detailed CAD layouts and specifications, focusing on hygiene zones and integration points.

Fabrication and Testing

Systems are built in controlled environments, with components often pre-assembled and tested for function.

Installation and Commissioning

On-site installation by trained technicians, followed by rigorous testing and operator training.

After-Sales Support and Maintenance

Provision of spare parts, maintenance schedules, and technical support to ensure long-term reliability.

Future Trends Shaping Food Conveyor Manufacturing

The industry is evolving rapidly. Key trends include the rise of hygienic design 2.0 with even easier disassembly, the integration of AI and machine vision for real-time quality control on the conveyor line, and a stronger push towards sustainability through energy-efficient drives and fully recyclable belt materials. Furthermore, the demand for flexible and modular systems is growing to accommodate shorter product lifecycles and frequent line changeovers.

Conclusion

Food conveyor manufacturers are indispensable partners in the global food supply chain. Their expertise in sanitary design, custom engineering, and innovative technology directly impacts a plant's productivity, compliance, and profitability. Investing time in selecting a manufacturer with proven experience, a robust portfolio, and a strong service ethos is not just a procurement decision—it's a strategic move towards building a safer, more efficient, and future-ready food production facility. The right conveyor system, expertly designed and built, becomes the reliable backbone of daily operations for years to come.