The commercial frozen food industry stands as a pillar of modern food supply chains, enabling global distribution, reducing waste, and providing convenience. Its remarkable growth and sophistication are intrinsically tied to the parallel evolution of the equipment used to process, store, and display frozen goods. From rudimentary ice houses to intelligent, automated systems, this journey reflects broader technological, economic, and societal shifts.

1. The Foundational Era: Mechanical Refrigeration

The story begins in the late 19th and early 20th centuries with the advent of mechanical refrigeration. Before this, preservation relied on natural ice, severely limiting scale and reliability. The invention of vapor-compression systems revolutionized the industry. Early commercial freezers were large, ammonia-based, and primarily used for bulk storage in warehouses and ice cream production.

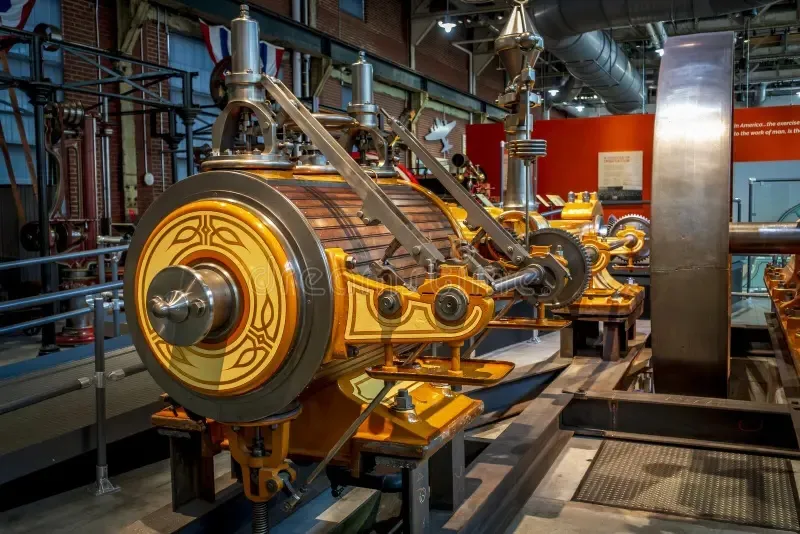

Early ammonia refrigeration compressors formed the backbone of the first generation of commercial freezing equipment.

These systems enabled the first true frozen food operations, though processing was largely manual, and freezing times were slow, often affecting product quality.

2. The Post-War Boom and the Rise of IQF

The post-World War II era saw a surge in consumer demand for frozen foods. A critical innovation was the development of Individual Quick Freezing (IQF) technology. Unlike slow freezing which creates large ice crystals, IQF uses extremely cold air blasted over individual items (like peas or shrimp), freezing them rapidly. This preserved texture, flavor, and nutritional value far more effectively.

Key IQF Equipment Innovations:

- Fluidized Bed Freezers: Use upward-blowing cold air to suspend and freeze small, particulate foods.

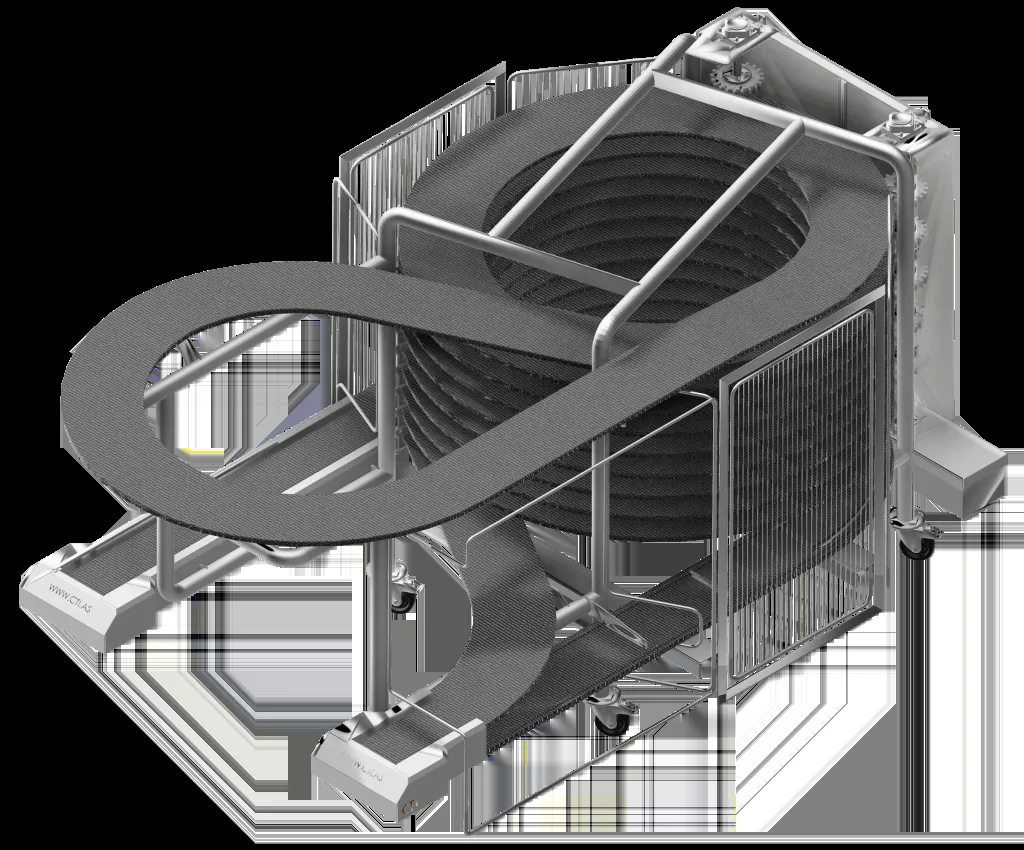

- Spiral Freezers: Utilize a continuous conveyor belt that spirals upward or downward through a freezing chamber, ideal for a wide range of products with longer retention times.

- Tunnel Freezers: A straight conveyor belt passes through a long tunnel with high-velocity cold air.

Spiral freezers became a workhorse of the industry, maximizing freezing capacity within a small footprint.

3. The Age of Automation and Efficiency

From the 1970s onward, the focus shifted towards automation, energy efficiency, and scale. Computer controls began to manage freezing cycles, while improvements in insulation (like polyurethane foam) and compressor technology (scroll and screw compressors) reduced energy consumption. The equipment also became more specialized.

| Era | Primary Technology | Scale & Control | Energy Focus |

|---|---|---|---|

| Foundational (Pre-1950) | Ammonia Compression, Batch Freezing | Manual, Bulk Storage | Very High Consumption |

| Expansion (1950s-1970s) | IQF (Fluidized, Tunnel), Plate Freezers | Semi-Automated, Continuous Processing | Moderate Efficiency Gains |

| Modern (1980s-Present) | Cryogenic (LN2, CO2), Spiral, Automated Systems | Fully Automated, PLC Controlled | High Efficiency, Sustainable Refrigerants |

The Cryogenic Revolution

The introduction of cryogenic freezers using liquid nitrogen (LN2) or carbon dioxide (CO2) represented a leap forward. These systems achieve ultra-fast freezing at extremely low temperatures (e.g., -196°C for LN2), resulting in superior product quality, especially for high-moisture or delicate items. They are also modular and require less floor space.

Cryogenic freezer tunnels use liquid nitrogen or CO2 for the fastest possible freezing, maximizing product quality.

4. The Modern Era: Intelligence, Sustainability, and Flexibility

Today's commercial frozen food equipment is defined by connectivity, data, and environmental responsibility.

Smart and Connected Systems

Modern freezers and cold storage warehouses are integrated with the Industrial Internet of Things (IIoT). Sensors monitor temperature, humidity, equipment performance, and product flow in real-time. Predictive analytics can forecast maintenance needs, preventing downtime. This ensures unparalleled consistency and traceability from processing to point-of-sale.

The Green Imperative

Responding to environmental regulations and corporate sustainability goals, the industry is phasing out ozone-depleting and high global-warming-potential (GWP) refrigerants. New systems utilize natural refrigerants like ammonia (in advanced, safer configurations), CO2, and hydrocarbons. Energy efficiency is paramount, driven by variable-speed drives, advanced heat recovery systems, and optimized thermal design.

Flexible and Compact Designs

Market demands for product variety and smaller batch production have led to more flexible equipment. Modular freezer units, multi-purpose spiral systems, and compact blast chillers/freezers allow producers to be more responsive. At the retail end, high-efficiency, glass-door display cases with LED lighting are now standard.

5. The Future: Emerging Trends

The evolution continues. Key future trends include:

- Advanced Robotics: For automated loading/unloading, packaging, and palletizing within frozen environments.

- Artificial Intelligence: AI will optimize entire freezing cycles in real-time for specific products, maximizing quality and minimizing energy use.

- Alternative Freezing Technologies: Research into technologies like high-pressure assisted freezing or magnetic resonance freezing promises to further enhance quality and efficiency.

- Hyper-Efficient Cold Chains: Integrated equipment ecosystems from processor to retailer, all communicating data to minimize temperature fluctuations and waste.

The future of frozen food logistics lies in fully automated, intelligent cold storage facilities.

Conclusion

The evolution of commercial frozen food equipment is a narrative of constant innovation driven by the dual engines of quality and efficiency. From the foundational power of mechanical cooling to the intelligent precision of today's smart systems, each technological leap has expanded the possibilities of frozen food. As sustainability and flexibility become ever more critical, the next generation of equipment will continue to shape how the world preserves, distributes, and enjoys its food.