Refrigeration technology has revolutionized how we preserve food, medicines, and create comfortable environments. While refrigeration systems vary widely in scale and application, they generally fall into four primary categories. Understanding these different systems is essential for engineers, technicians, and anyone interested in cooling technology. Each system operates on distinct thermodynamic principles and offers unique advantages for specific applications.

1. Vapor Compression Refrigeration System

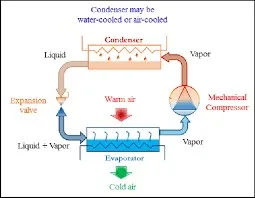

The vapor compression system is the most common refrigeration technology found in households, commercial establishments, and industrial applications worldwide. This system operates on a closed loop cycle that involves four key components: compressor, condenser, expansion device, and evaporator.

Diagram showing the four components of vapor compression system: compressor, condenser, expansion valve, and evaporator connected in a circuit with refrigerant flow directions.

Diagram showing the four components of vapor compression system: compressor, condenser, expansion valve, and evaporator connected in a circuit with refrigerant flow directions.

The refrigeration process begins when the compressor receives low-pressure refrigerant vapor from the evaporator and compresses it, significantly increasing its temperature and pressure. This high-pressure, high-temperature vapor then travels to the condenser, where it releases heat to the surrounding environment (air or water) and condenses into a liquid. The liquid refrigerant passes through an expansion device (capillary tube or thermal expansion valve), where its pressure and temperature drop dramatically. Finally, the cold refrigerant enters the evaporator, where it absorbs heat from the space being cooled and evaporates back into a vapor, completing the cycle.

Applications of Vapor Compression Systems

Vapor compression refrigeration systems dominate numerous applications due to their efficiency and reliability:

| Application Sector | Examples | Typical Refrigerants Used |

|---|---|---|

| Domestic | Household refrigerators, freezers, air conditioners | R-134a, R-600a (isobutane) |

| Commercial | Supermarket display cases, walk-in coolers, restaurant equipment | R-404A, R-407C |

| Industrial | Cold storage warehouses, food processing plants, pharmaceutical storage | R-717 (ammonia), R-744 (CO₂) |

| Transport | Reefer trucks, shipping containers, railway refrigeration | R-410A, R-452A |

Advantages and Limitations

Vapor compression systems offer high coefficient of performance (COP), reliable operation, and the ability to achieve very low temperatures. However, they typically use synthetic refrigerants with global warming potential, require regular maintenance, and consume significant electrical energy.

2. Absorption Refrigeration System

Absorption refrigeration systems represent an alternative technology that uses heat energy instead of mechanical energy to drive the cooling process. These systems are particularly valuable in situations where waste heat or renewable thermal energy is available.

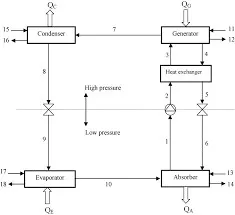

Schematic diagram showing generator, condenser, evaporator, absorber, and solution pump in an absorption refrigeration cycle.

Schematic diagram showing generator, condenser, evaporator, absorber, and solution pump in an absorption refrigeration cycle.

The absorption cycle differs significantly from vapor compression. Instead of a compressor, it uses a chemical process involving an absorbent (typically lithium bromide or ammonia) and a refrigerant (typically water or ammonia). The process begins in the generator, where heat application separates the refrigerant from the absorbent solution. The refrigerant vapor then moves to the condenser, where it liquefies. After passing through an expansion device, the liquid refrigerant enters the evaporator and absorbs heat, transforming back into vapor. This vapor then moves to the absorber, where it combines with the weak absorbent solution, creating a strong solution that is pumped back to the generator to repeat the cycle.

Applications of Absorption Systems

Absorption chillers are particularly valuable in specific contexts:

- Cogeneration plants: Utilizing waste heat from power generation

- Solar cooling: Using solar thermal collectors as energy source

- Industrial processes: Where waste process heat is available

- Natural gas processing: Using waste heat from compression

- Remote locations: Where electricity is scarce but heat sources are available

Advantages and Limitations

Absorption systems can operate with thermal energy sources (including waste heat and solar energy), have fewer moving parts (potentially increasing reliability), and use environmentally friendly refrigerants like water or ammonia. However, they typically have lower COP values than compression systems, require larger physical footprints, and have higher initial costs.

3. Thermoelectric Refrigeration System

Thermoelectric refrigeration systems operate on the Peltier effect, where electrical current creates a temperature difference across a junction of two different materials. When direct current passes through thermoelectric modules, heat is transferred from one side to the other, creating a cooling effect on one side and a heating effect on the opposite side.

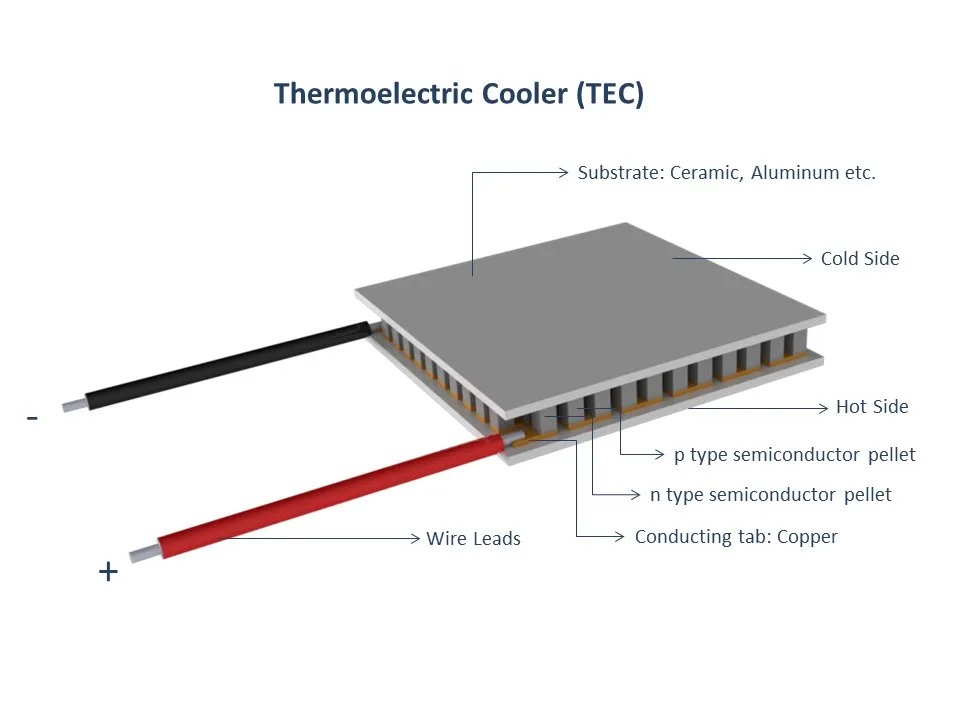

Close-up image of a Peltier module showing semiconductor elements between ceramic plates with electrical connections.

Close-up image of a Peltier module showing semiconductor elements between ceramic plates with electrical connections.

These solid-state devices contain p-type and n-type semiconductor materials sandwiched between ceramic plates. When DC current flows through the circuit, electrons move from the p-type to the n-type material, carrying heat with them. This creates a cold junction on one side and a hot junction on the other. The hot side must be connected to a heat sink to dissipate the accumulated heat effectively.

Applications of Thermoelectric Systems

While limited in capacity, thermoelectric cooling finds important niche applications:

| Application Area | Specific Uses | Advantages in Context |

|---|---|---|

| Electronics Cooling | CPU coolers, laser diode temperature stabilization | Precise temperature control, compact size |

| Medical & Laboratory | Portable medical refrigerators, DNA cyclers | No moving parts, vibration-free operation |

| Automotive | Seat coolers, portable coolers | DC power compatibility, compact design |

| Aerospace | Satellite component cooling | Reliability in zero gravity, minimal maintenance |

Advantages and Limitations

Thermoelectric systems offer solid-state operation with no moving parts (resulting in high reliability), precise temperature control, compact size, and ability to both cool and heat by reversing current direction. However, they have relatively low efficiency, limited capacity for large cooling loads, require significant electrical power input, and need effective heat rejection systems.

4. Evaporative Cooling System

Evaporative cooling systems utilize the natural principle of water evaporation to reduce air temperature. When water evaporates, it absorbs significant amounts of latent heat from the surrounding environment, producing a cooling effect. These systems are among the oldest and simplest forms of air conditioning.

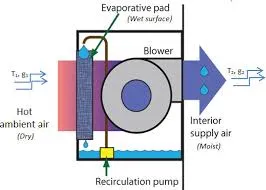

Cross-sectional diagram showing how warm air passes through water-moistened pads in an evaporative cooler, emerging as cooled air.

Cross-sectional diagram showing how warm air passes through water-moistened pads in an evaporative cooler, emerging as cooled air.

Basic evaporative coolers consist of a fan that draws warm air through water-moistened pads. As the air passes through these pads, water evaporates and the air temperature drops significantly while humidity increases. The cooled air is then circulated into the living or working space while warm air is exhausted. More advanced indirect evaporative systems separate the evaporation process from the supply air, preventing humidity increase in the cooled space.

Applications of Evaporative Systems

Evaporative cooling is particularly effective in specific climates and applications:

- Arid climates: Where low humidity makes evaporation highly effective

- Industrial cooling: Factories, warehouses, and agricultural buildings

- Data centers: Using indirect systems for efficient cooling

- Residential cooling: In dry climates as an energy-efficient alternative to conventional AC

- Green building design: As part of passive cooling strategies

Advantages and Limitations

Evaporative cooling systems offer significant energy efficiency (using up to 75% less energy than vapor compression AC), lower initial costs, simplicity of design and operation, and use of water as the only refrigerant (environmentally benign). Limitations include effectiveness limited to dry climates, water consumption requirements, limited temperature control precision, and potential for microbial growth if not properly maintained.

Comparison of Refrigeration Systems

Each refrigeration system type offers distinct advantages depending on the specific application requirements, available energy sources, and environmental conditions. The following comparison highlights key differences:

| System Type | Energy Source | Typical COP | Temperature Range | Best Application Fit |

|---|---|---|---|---|

| Vapor Compression | Electrical (mechanical) | 2.0-4.0+ | -50°C to 10°C | Most applications, especially where electricity is reliable |

| Absorption | Thermal (heat) | 0.6-1.2 | -10°C to 10°C | Where waste heat or solar thermal is available |

| Thermoelectric | Electrical (DC) | 0.3-0.6 | 5°C to 40°C below ambient | Small-scale, precise temperature control applications |

| Evaporative | Electrical (fan/pump) | 5-20+ (EER) | Approach wet bulb temperature | Arid climates, industrial spaces, energy-efficient buildings |

Future Trends in Refrigeration Technology

The refrigeration industry continues to evolve with emerging technologies and environmental concerns driving innovation. Key developments include natural refrigerants with low global warming potential, magnetic refrigeration using the magnetocaloric effect, improved system integration with renewable energy sources, and smart controls with IoT connectivity for optimized performance. As sustainability becomes increasingly important, systems that minimize environmental impact while maintaining efficiency will likely dominate future refrigeration markets.

Understanding these four fundamental refrigeration system types provides a foundation for selecting appropriate cooling technologies for specific applications, optimizing energy efficiency, and making informed decisions about refrigeration needs in various contexts from domestic to industrial scale.

jjjjjjExplore the four main refrigeration systems: vapor compression, absorption, thermoelectric, and evaporative cooling. Understand how each system works, their applications, advantages, limitations, and comparative performance in various cooling scenarios.zzzzzz