Introduction to AI Integration in Agricultural Processing

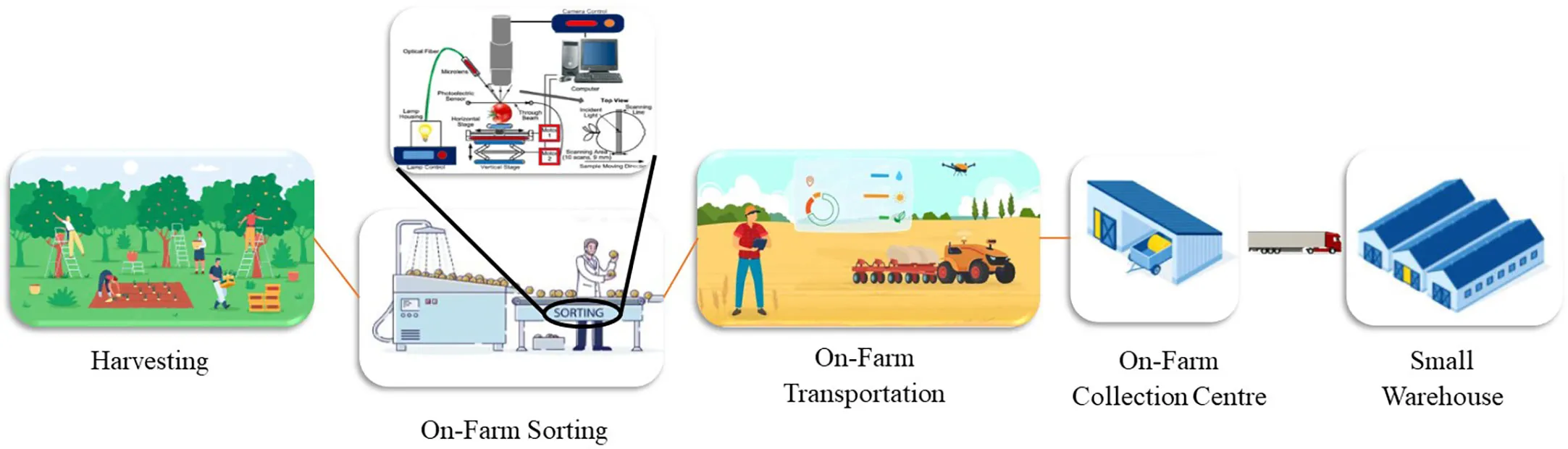

The agricultural industry is undergoing a significant transformation with the integration of artificial intelligence into processing machinery. This technological revolution is particularly evident in fruit and vegetable processing, where AI-driven systems are enhancing efficiency, quality control, and sustainability. The convergence of computer vision, machine learning, and robotics is creating intelligent processing systems that can adapt to varying product characteristics and optimize operations in real-time.

Current Applications of AI in Processing Equipment

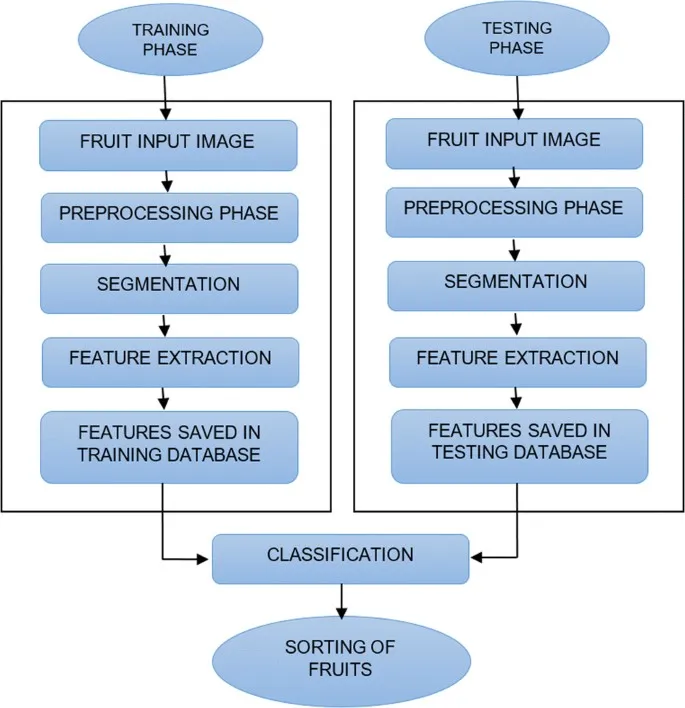

Modern fruit and vegetable processing facilities are increasingly adopting AI technologies to streamline operations. Computer vision systems equipped with high-resolution cameras and sophisticated algorithms can identify defects, sort products by size and quality, and remove contaminants with unprecedented accuracy. These systems can process thousands of items per hour while maintaining consistent quality standards that surpass human capabilities.

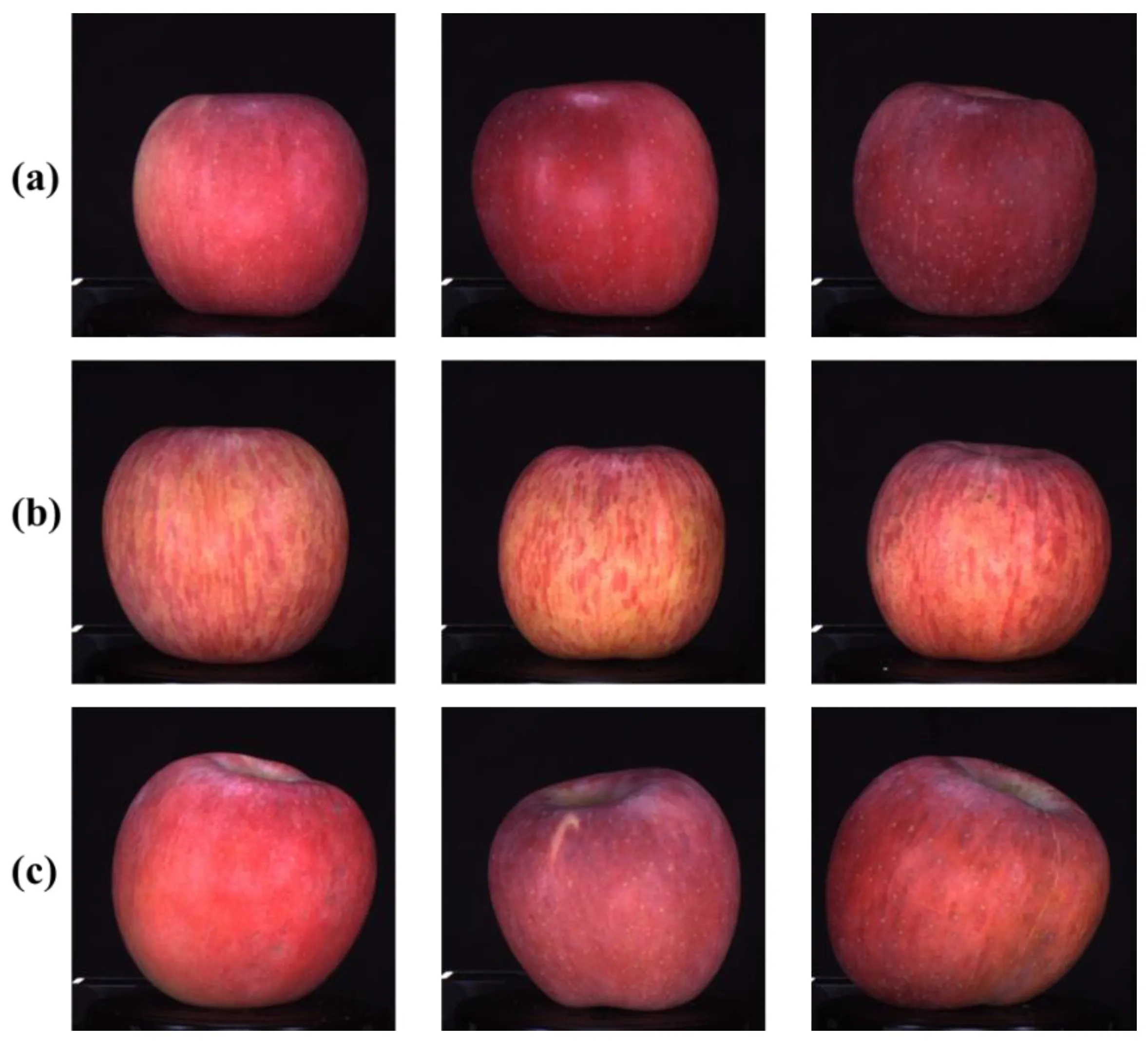

Quality Assessment and Sorting

AI-powered sorting machines utilize deep learning algorithms to analyze multiple parameters simultaneously, including color, size, shape, and surface defects. These systems can distinguish between acceptable variations and actual defects, reducing false rejections and maximizing yield. The technology continuously improves through machine learning, adapting to new varieties and seasonal variations in produce characteristics.

Predictive Maintenance

AI algorithms monitor equipment performance data to predict potential failures before they occur. By analyzing vibration patterns, temperature fluctuations, and operational parameters, these systems can schedule maintenance during planned downtime, minimizing unexpected breakdowns and extending machinery lifespan.

Advanced AI Technologies Transforming Processing

Computer Vision and Machine Learning

The combination of computer vision and machine learning represents the core of AI implementation in processing machinery. These systems can identify subtle patterns and anomalies that are invisible to the human eye, enabling precise grading and sorting based on multiple quality parameters simultaneously.

| Technology | Application | Benefits | Accuracy Rate |

|---|---|---|---|

| Computer Vision | Quality sorting and defect detection | Reduced labor costs, consistent quality | 95-99% |

| Machine Learning | Predictive maintenance | Reduced downtime, longer equipment life | 85-92% |

| Robotics | Automated processing and packaging | Increased speed, reduced contamination | 98%+ |

| IoT Sensors | Real-time monitoring | Improved efficiency, data collection | 99% |

Robotic Processing and Automation

AI-driven robotics are revolutionizing how fruits and vegetables are processed. These systems can handle delicate products without causing damage, perform precise cutting and peeling operations, and adapt to natural variations in size and shape. Advanced grippers and end-effectors designed specifically for agricultural products ensure minimal waste and maximum product integrity.

Future Trends and Innovations

AI-Optimized Supply Chain Integration

The future will see greater integration between processing machinery and broader supply chain systems. AI algorithms will optimize processing schedules based on predicted demand, transportation logistics, and shelf-life considerations. This holistic approach will minimize waste and ensure fresher products reach consumers.

Adaptive Processing Systems

Next-generation processing machinery will feature self-optimizing capabilities, where systems automatically adjust processing parameters based on real-time analysis of incoming product quality. These adaptive systems will maximize yield while maintaining quality standards, responding dynamically to variations in raw material characteristics.

Sustainability and Waste Reduction

AI technologies will play a crucial role in enhancing sustainability within the processing industry. By optimizing processing parameters and identifying opportunities for byproduct utilization, AI systems will help reduce energy consumption, water usage, and overall environmental impact while maximizing the utilization of raw materials.

| Metric | Current Performance | Projected with AI Implementation | Improvement |

|---|---|---|---|

| Sorting Accuracy | 85-90% | 97-99% | 12-14% |

| Processing Speed | Medium | High | 40-60% |

| Yield Optimization | 75-80% | 88-92% | 13-17% |

| Energy Consumption | Baseline | Reduced | 15-25% |

| Labor Requirements | High | Low | 50-70% |

Challenges and Implementation Considerations

Technical Challenges

Implementing AI in fruit and vegetable processing presents several technical challenges, including the need for robust algorithms that can handle the natural variability of agricultural products, integration with existing equipment, and the requirement for substantial computational resources. Additionally, maintaining these sophisticated systems requires specialized technical expertise.

Economic Considerations

While AI technologies offer significant long-term benefits, the initial investment can be substantial. Processors must carefully evaluate return on investment, considering factors such as labor savings, quality improvements, reduced waste, and increased throughput. The decreasing cost of computing power and sensors is making AI implementation increasingly accessible to smaller operations.

Conclusion: The Path Forward

The integration of artificial intelligence into fruit and vegetable processing machinery represents a paradigm shift in agricultural technology. As AI systems become more sophisticated and cost-effective, they will increasingly become standard features in processing facilities worldwide. The future promises fully autonomous processing plants where AI-driven systems manage everything from raw material intake to final packaging, optimizing every aspect of the operation for maximum efficiency, quality, and sustainability. The industry stands at the threshold of a new era where intelligent machines and human expertise combine to create unprecedented levels of productivity and food safety.