Fruit processing is a critical component of the global food industry, transforming perishable fresh produce into stable, safe, and convenient products that can be enjoyed year-round. By applying various preservation techniques, processors inhibit microbial growth, slow enzymatic activity, and prevent spoilage. Among the numerous technologies available, three methods stand out as the most prevalent and foundational: Thermal Processing, Dehydration or Drying, and Freezing. Each method employs distinct principles to extend shelf life while aiming to preserve the fruit's sensory qualities and nutritional value as much as possible.

1. Thermal Processing

Thermal processing involves the application of heat to destroy microorganisms and deactivate enzymes that cause spoilage and foodborne illness. This is one of the oldest and most reliable methods for achieving long-term shelf stability at ambient temperatures.

Canning and Bottling

Fruits are placed in sealed containers (cans or glass jars) and heated to a specific temperature for a predetermined time. The heat treatment, followed by hermetic sealing, creates a sterile environment inside the container. Common examples include canned peaches, fruit cocktails, and jams.

Pasteurization

A milder heat treatment compared to canning, pasteurization is designed to destroy pathogenic bacteria and reduce spoilage organisms without significantly altering the fruit's flavor and texture. It is commonly used for fruit juices, purees, and nectars.

2. Dehydration or Drying

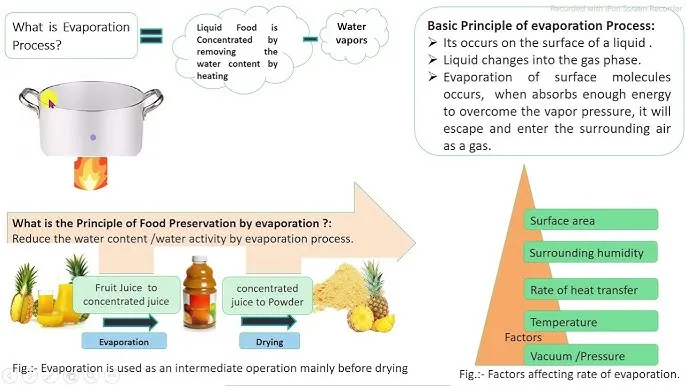

This method removes the majority of water from fruit, which is essential for microbial growth and biochemical reactions. By reducing water activity, drying effectively halts spoilage. The result is a lightweight, concentrated product with a significantly extended shelf life.

Sun Drying and Air Drying

The traditional method where fruits like apricots, figs, and grapes (to make raisins) are laid out in the sun. Controlled air drying uses circulated warm air in cabinets or tunnels for more consistent results.

Advanced Drying Technologies

Modern methods include freeze-drying (sublimation of ice under vacuum), which preserves structure and nutrients exceptionally well, and spray drying (for fruit juices into powders).

3. Freezing

Freezing preserves fruit by turning residual moisture into ice, making it unavailable for microbial growth and slowing down chemical and enzymatic reactions. It is renowned for best retaining the fresh taste, color, and nutritional profile of fruits.

Individual Quick Freezing (IQF)

A rapid freezing technique where individual fruit pieces (like berries, diced mango) are frozen separately, preventing them from clumping together and preserving their individual texture.

Bulk Freezing

Fruits are packed in large containers or bags and frozen in blast freezers. Often used for fruits destined for further processing (e.g., smoothie mixes, bakery fillings).

Comparison of the Three Fruit Processing Methods

The following table summarizes the key characteristics, advantages, and typical applications of each primary processing method:

| Method | Core Principle | Key Advantages | Common Fruit Products | Shelf Life (Approx.) |

|---|---|---|---|---|

| Thermal Processing | Heat destruction of microbes/enzymes | Room-temperature storage; long shelf life; safety | Canned peaches, fruit jams, juices, pie fillings | 1-5 years |

| Dehydration | Removal of water (moisture) | Lightweight; concentrated flavor; no refrigeration needed | Dried apricots, raisins, banana chips, fruit powders | 6 months - 1 year+ |

| Freezing | Lowering temperature to inhibit microbial/enzymatic activity | Best retention of fresh qualities, color, and nutrients | IQF berries, frozen mango chunks, fruit purees | 6 - 18 months (frozen) |

In conclusion, the choice of processing method depends on the desired product characteristics, target market, nutritional goals, and economic factors. Often, these methods are used in combination (e.g., freezing dried fruit for quality retention, or pasteurizing before freezing) to optimize quality and safety. Understanding these three fundamental methods—thermal, dehydration, and freezing—provides essential insight into how fruits transition from fragile, seasonal produce to the diverse, stable products found on grocery shelves worldwide.

Summary

Fruit processing relies on three core methods to prevent spoilage and extend usability. Thermal processing uses heat (canning, pasteurization) to sterilize fruit for ambient storage. Dehydration removes water through sun, air, or advanced drying to create shelf-stable, concentrated products. Freezing preserves fruit by lowering its temperature, best maintaining fresh qualities. Each technique balances shelf life, safety, nutrition, and sensory attributes to deliver a wide array of fruit products to consumers.